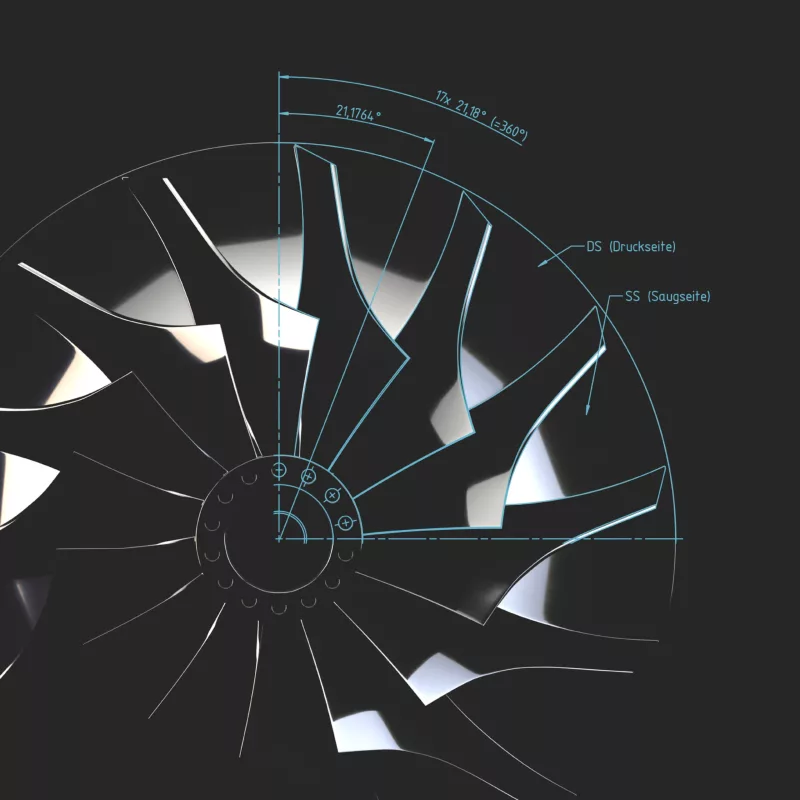

Inner channels polishing with DLyte

Most of the applications requiring internal polishing requires low roughness and absence of burrs to increase velocity of the flow and reduce turbulences due to lower friction, an inert, smooth surface with few sites for trapping impurities and avoiding bio-film formation and resistance to corrosion as the parts are exposed to oxidizing agents. Current surface finishing technologies as abrasive mechanical, chemical and manual finishing are not able to treat effectively those cases thus achieving suboptimal results.

DLyte performs cost-effective, reliable, superior quality and inert internal surface finishing of metal parts using the novel Dry Suspension electropolishing process. It encompasses the benefits of mechanical and electro-chemical processes in one single process since DLyte improves the results of alternatives procedures for treatment of inner channels as abrasive flow machining and liquid electropolishing.

The solution is able to deliver surfaces with an average roughness Ra below 0,3 microns and improving the corrosion resistance versus raw and liquid electropolished surfaces thus achieving the targets of ultrahigh-purity and high-purity components. Straight channels or right and obtuse angles with a minimum diameter of 4 mm can be internally polished.

Economic and environmental benefits

Inner channels polishing Success Cases

Common applications