Postprocessing Additive Manufacturing parts

Compared to traditional manufacturing techniques, it also reduces intermediate processes such as tooling production, making it possible to obtain parts faster and more cost effectively in short series, and prototyping and custom products.

Postprocessing AM parts supposes around 30 percent of the total cost and 50 percent of the total time of production of these pieces. The lack of automatic surface finishing procedures is a big barrier for the development of AM industry compared to traditional manufacturing.

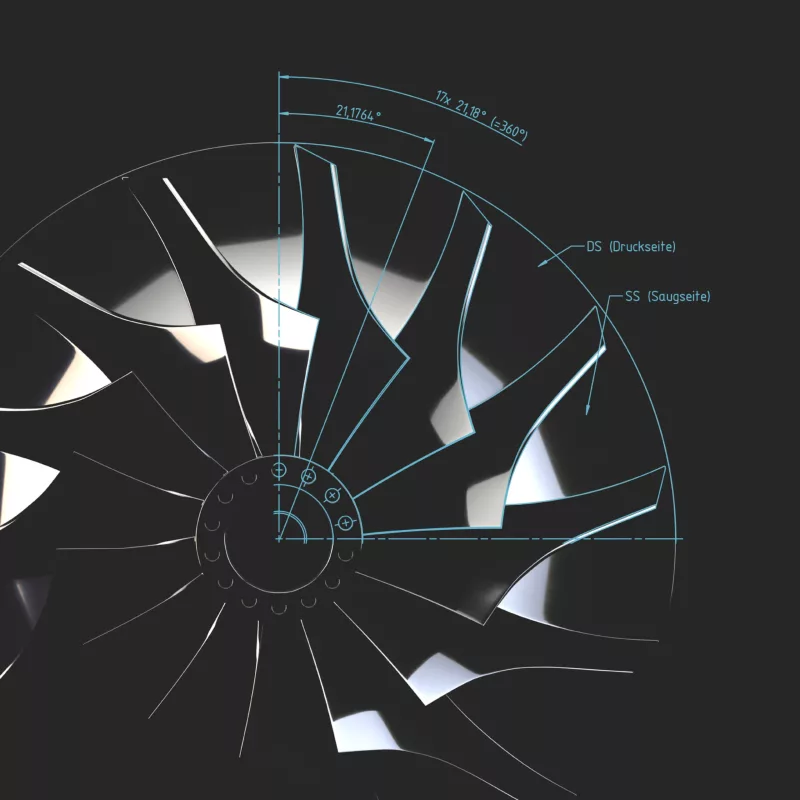

DLyte performs automated effective surface finishing of metal additive manufacturing parts, thus improving dramatically the performance and lifespan of them. The patented technology based on dry electropolishing can improve drastically surfaces without changing the geometry.

The DLyte surface finishing selectively improves metal surfaces, leading to the desired surface quality on workpieces. The material range also includes very hard to erode materials as nickel alloys, titanium alloys, and cemented carbides.

DLyte’s DryLyte is considered the surface finishing technology for metal additive manufacturing parts, with the best balance between roughness reduction and geometry preservation. It also achieves the lowest surface roughness, which is at least two times lower than the next-best alternative on the market. It is also suitable to finish delicate and fragile pieces without harming them, as the process does not use abrasive nor strong mechanical forces.

In comparison with abrasive, those methods do not stress the surface, do not cause scratches over smooth surfaces, and do not produce inclusions on the metal surface, as abrasive does. Another advantage of those processes versus abrasive is that they do not create dust remnants or noise.

The DryLyte Technology has been awarded the TCT Award for Excellence in Additive Manufacturing Post-Processing in 2018 and 2022.

Benefits of a proper finishing in AM metal parts

Surface finishing makes it possible to selectively achieve the desired surface quality on workpieces made from a wide variety of materials, such as, steel, stainless steel, aluminum, or brass. Since the process is equivalent to deburring, burrs are removed from inaccessible or difficult-to-access locations on a piece, while its edges are also deburred and rounded off.

The quality of the surface finishing will be essentially determined by the type and setting of the machine, as well as the material of the parts.

It is quite common to carry out this process with abrasive substances, whose use may generate rougher surfaces than less abrasive ones. Nonetheless, the roughness pattern can also be controlled by selecting specific geometries of the abrasive bodies, but also by using less aggressive processes, like DLyte’s solutions for electropolishing.

If you have any query or doubt about surface finishing in AM metal parts, do not hesitate to contact our team of experts.

Economic and environmental benefits

Common applications