Mirror Finishing with DLyte

A mirror finish is a highly-polished finish, characterized by a bright, shiny, reflective metal surface. It can be found in aesthetic parts, such as architecture, transportation, consumer goods, or metal pieces aimed at fashion and luxury industry, but also in metal pieces produced for food, pharma and medical applications. A high-quality mirror finish is not only visually appealing, but the gradual removal of surface scratches through polishing processes reduces indentations or grooves on metal, which may contain contaminants, such as dirt or bacteria. Those surfaces are easy to clean, more corrosion resistant and allows detection of design flaws.

Besides a significant aesthetical improvement, mirror-finished pieces are much less susceptible to contamination than rough surfaces. Smooth surfaces are achieved by working with different grits in mechanical applications to gradually remove scratches and blemishes from the metal. For example, in more technical terms, mirror-finished steels have an Ra index between 0.15 (6 microinches) and 0.3 (12 microinches)- Ra. That is: concerning roughness average, which measures the microscopic peaks and troughs on the surface of the metal, the lower the number, the fewer or smaller the peaks and troughs, which means that polished metal surface looks smoother and more brilliant.

Dry electropolishing processes achieve homogeneous results across the surface and eliminates micro-scratches and milling lines. The system works efficiently at micro and macroscopic level. They also enhance negative surface skewness (rsk), increasing the surface bearing contact area —therefore, allowing uniform lubricant film distribution—, improving the bearing ratio and reducing the friction between metal parts. In addition, dry electropolishing respects tolerances and preserves the initial shape of pieces, even the cutting edges, avoids generating grinding texture patterns. It offers best-in-class surface roughness (Ra under 0.01 micrometers) and protection against corrosion.

Economic and environmental benefits

Short processing time in a compact design

No devices to manage sewage and sludge

High profitability and short payback time

Environmentally friendly

Protects workers' health

Mirror Finishing Success Cases

Common applications

01.

Stents and other medical components

02.

Needles and surgical instruments

03.

Mixers, agitators and can seamers

04.

Compression mold tools

05.

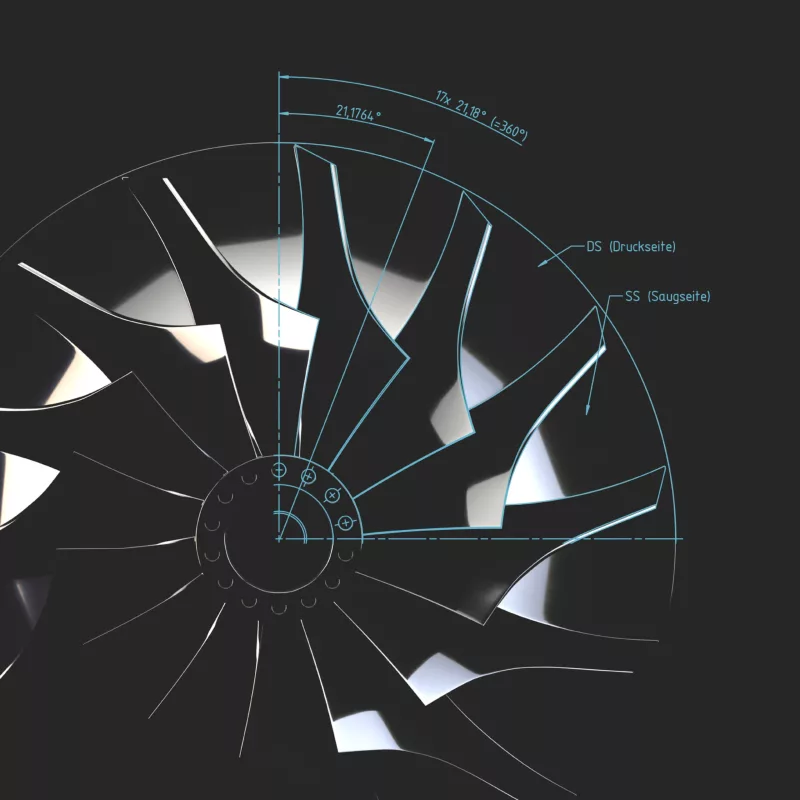

Gears and drive units

06.

Cutting tools, drill bits, threaded formers and taps

07.

Carbide inserts

08.

Stamping, pressing and forming tools, punches

09.

Inner forming dies

10.

Rings, pendants, bracelets and earrings

11.

Belt buckles, bag inserts, eyewear and luxury pens

12.

Cutlery, musical instruments, taps and handles

13.

Figurines, ornaments and decorative home appliances

14.

PVC coated workpieces

15.

Mandrels/shank tool holder