Precision Surface Finishing with DLyte

It is a fact that today’s manufacturers demand extremely consistent and reliable processes from metal part producers. Besides this, according to current market demands, long-term durability of parts must be reproducible and performance must be guaranteed to stabilize the quality of precision components in a wide range of industries.

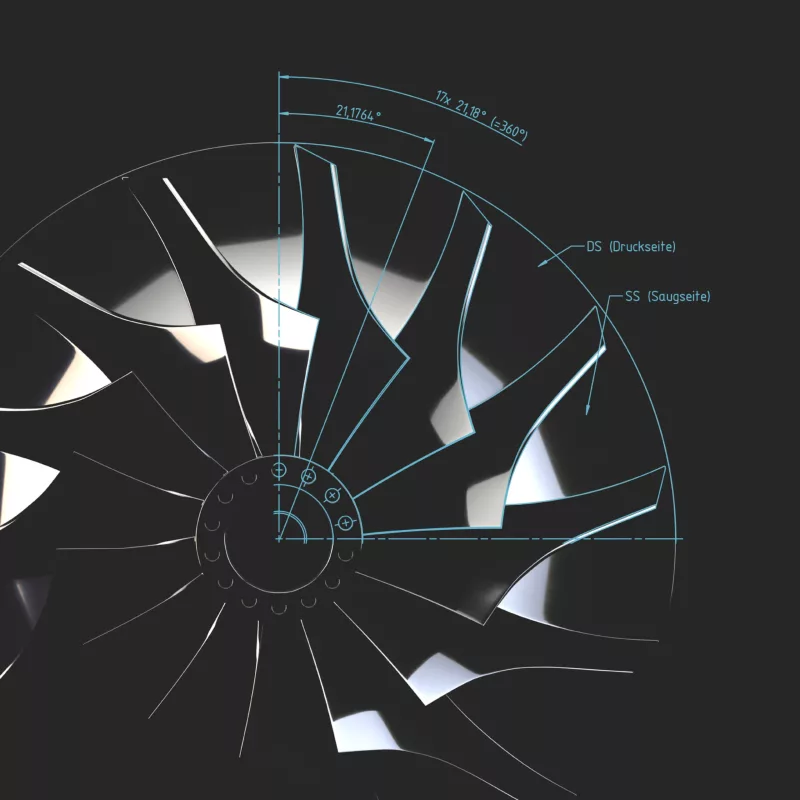

Some of the parts needing precision surface finishing processes are tools, transmission parts, turbines and fitting parts with functional applications.

Thanks to DLyte, it is possible to obtain high standard for surface flatness, smoothness and geometric precision in this kind of pieces. Due to its accuracy, low material removal and edge preservation it is specially well suited for parts that require superior surface finishing keeping completely the edges and tight tolerances that cannot be treated automatically otherwise. At its turn, dry electropolishing allows automated processes that guarantee consistent results among batches.

Economic and environmental benefits

Precision Finishing Success Cases

Common applications