Smoothing Metal Surfaces with DLyte

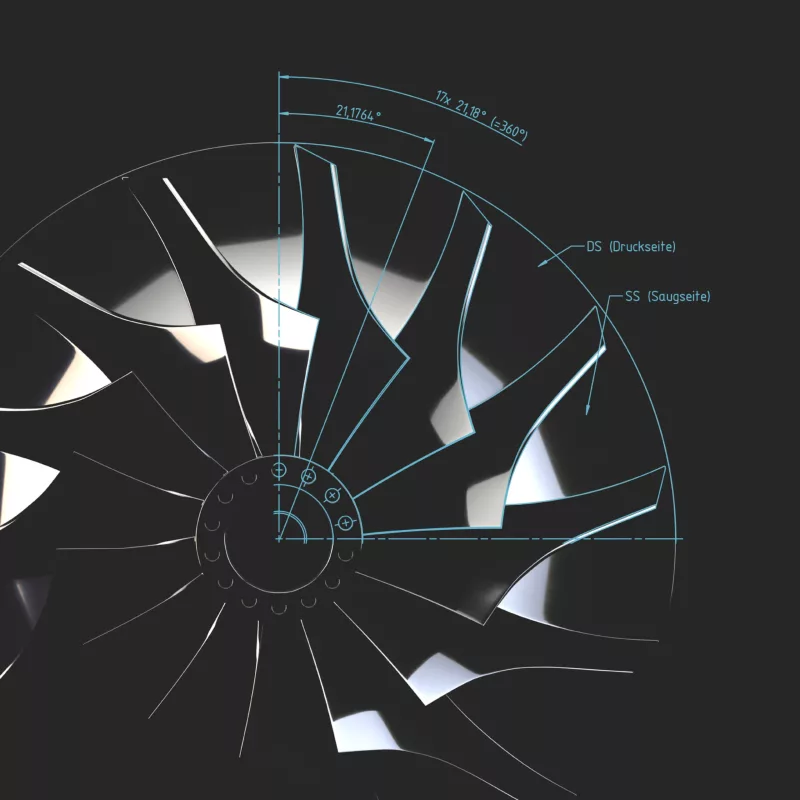

DLyte Surface finishing selectively smooth metal surfaces to the desired surface quality on workpieces made from a wide variety of materials, such as, steel, stainless steel, aluminum or brass. Smoothing operations improve parts aesthetics and quality perception, optimize wear and tear, minimize energy consumption and noise.

Dry electropolishing processes achieve homogeneous results across the surface and eliminates micro-scratches and milling lines. The system works efficiently at micro and macroscopic level. It enhances negative surface skewness (rsk), increasing the surface bearing contact area —therefore, allowing uniform lubricant film distribution—, improving the bearing ratio and reducing the friction between metal parts and the noise.

In addition, dry electropolishing respects tolerances and preserves the initial shape of pieces, even the cutting edges, avoids generating grinding texture patterns. It offers high ratio of roughness reduction and protection against corrosion.

Economic and environmental benefits

Common applications