_ Finishing processes

Precision finishing

More and more demanding quality standards on the market are dramatically increasing the importance of precision surface finishing processes. These treatments improve the aesthetic appearance of metal parts, but also their mechanical and physical characteristics, corrosion resistance and lifespan, among others.

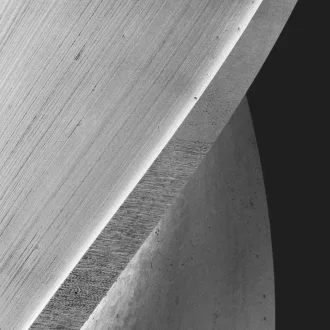

Smoothing

Processes related to smoothing metal surface allow to achieve uniformity of product for appearance’s sake, and to be safe for touching without being scratched to shreds by unfinished roughness. For moving parts, a smooth finish cuts down on friction loss, without getting into coatings.

Mirror finishing

A mirror finish is a highly-polished finish, characterized by a bright, shiny, reflective metal surface. A high-quality mirror finish is not only visually appealing, but the gradual removal of surface scratches reduces indentations or grooves on metal, which may contain contaminants, such as dirt or bacteria.

Deburring

Deburring is a material modification process that increases the final quality of the product by removing impurities with a negative impact the on the appearance of a smooth machined surface, like sharp edges or burrs, left by bending, cutting, piercing, shearing and compressing materials.

Rounding

Rounding cutting edges is crucial for the design and geometry of cutting tools in metal machining. Cutting edge geometry determines the thermo-mechanical stresses on the tool. By employing edge preparation, tool life, cutting performance, and the quality of the machined surface can be improved.

Corrosion resistance

AM Post-processing

Surface roughness of AM parts can vary depending on the technology used and parameters applied, and affects fatigue, corrosion resistance and friction properties. In order to improve the surface quality, electropolishing is postulated as the most promising the treatment to reduce roughness and defects.

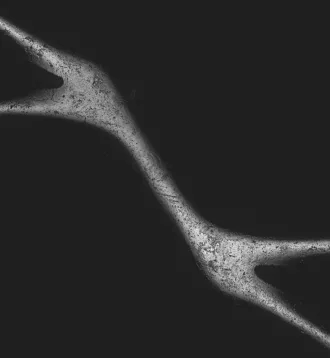

Inner channels

Surface quality requirements of internal surfaces, inner channels and complex parts with blind holes have increased during the last years specially in case of injection molding, aerospace, automotive, medical, food and pharma, semiconductors and gas and fluid flow applications.

_ Industries

Aerospace

Surface finishing operations play an extremely important role in aerospace and energy sectors, since it helps to improve efficiency, while increasing reliability and durability. These parts must withstand high stress corrosive conditions, high loads with long-term lifespan and meeting demanding cycle life specifications.

Automotive

Surface finishing solutions are utilized at every level of the automotive pipeline, from garage maintenance and car restoration to manufacturers’ demands. One of the most challenging aspects has to do with safety, since the result of the surface finishing process is closely linked to the vehicle performance and reliability.

Dentistry

Dental laboratories use dry electropolishing to improve surface quality of cobalt-chrome and titanium dental parts. Smoothing, cleaning and eliminating small imperfections from removal dental prosthetics and other implanted dental parts expands their lifespan pieces and can extend the life of dental components from the inside out.

Food & Pharma

Metal components produced for food, beverages, packaging and pharma industries must comply with challenging surface finishing standards. Those surfaces should be ultra-smooth, precision finishing, thus avoiding areas for bacteria grow. DLyte achieves superior results than any other surface finishing method.

Jewelry & Fashion

These industries require a perfect surface quality as the purpose of the piece is mainly aesthetic and its value depends on a good looking. Complex geometries in jewels are hard to polish with traditional polishing methods and electropolishing is one of the techniques utilized for a better homogeneity and standardization.

Medical device

Cleanability, biocompatibility, corrosion resistance, pathogen resistance and a smooth surface without defects are crucial to comply with the function and demand on quality of the medical industries. Improving the surface’s quality on implants, instruments and equipment components increases functionalities as well as their lifespan.

Toolmaking

Overcoming the drawbacks of tool finishing is one of the main challenges in the field of surface finishing solutions, in order to achieve the lowest roughness on flat surfaces. This is why DLyte has specially created new electropolishing technologies to carry out the most challenging freeform surfaces polishing.

_ Technology

Immersion

DryLyte is a patented technology for grinding and polishing metals by ion transport using free solid bodies. It works by combining the electrical flow created by high-precision rectifier. This results in an ion exchange, removing material from the peaks of roughness.

Projection

Our new Electro-Blasting technology, released in 2021, is a new solution that provides a stream of solid-electrolyte particles propelled by a non-conductive liquid media to improve the surface quality. The media is projected towards a localized area of the piece.

_ Industrial solutions

_ Dental solutions

Desktop series

Accessible to small laboratories, workshops, workrooms and SMEs needing a cost-effective solution for metal surface finishing processes. From grinding to mirror finishing, this new set-up offers a new easy way to process any casting, sintering or milling metal parts.

Compact series

An efficient range of solutions to meet the requirements of dental, medical and industrial sectors, depending on finishing needs, production quantities or part dimensions. Ensures high scalability and performance. A solution for the most common metals and alloys.

PRO500 series

The most advanced, powerful and versatile surface-finishing machine for mass production on the market. It performs high-quality metal surface-finishing better, faster and more efficiently with processing times ten times better than current technologies.

DLyte 10,000

The most powerful modular unit for polishing large, heavy and complex pieces to be totally integrated in any production line. The robot module allows to treat metals and alloys in a fast, and cost-efficient way. It counts with a precise 6-axis mechanical movement.

DLyte eBlast

Projected dry electropolishing for focused surface finishing in complex geometries and heavy or large parts. It provides a stream of solid-electrolyte particles propelled by a non-conductive liquid media to achieve the best surface quality results of metal parts.

Dental series

An efficient range of solutions to meet the requirements of dental sectors, depending on finishing needs, production quantities or part dimensions. Ensures high scalability and performance. A solution for the most common metals and alloys.

DLyte Mini

It is perfect for low production volumes or as a complementary device to existing DLyte equipment. It can be used as a secondary, quick-step process to achieve a superior shine.

News

Find out more about our corporate news, the latest commercial developments and upcoming events. From the main international trade shows to the most innovative launches, we invite you to learn more about GPAINNOVA’s brand DLyte. Stay tuned for all the projects in which we are involved!

Exhibitions

Our aim is to be as close as possible to our customers. This is why GPAINNOVA attends every year more than 40 international trade shows dedicated to the dental, healthcare, and industrial sector, including key events such as Formnext or EMO Milano. Check all our upcoming events here!

Webinars

Innovation is in our DNA. Our business group is continuously investing and focusing on getting better to meet the real needs and demands of the industry, which are increasingly changing. Do not miss them out! Learn more about our newest technological developments: machines, fixturing, electrolyte and much more.

Media

Would you like to see how our machines and our disruptive DryLyte Technology work? Do you want to know how they can help you automate your surface finishing processes and make them more cost-efficient and environmentally-friendly? Take a look at our video gallery and find out more about our machinery!

History

Created to overcome these challenges, DryLyte is the basis of DLyte, a technological system that automates, simplifies, and standardizes the post-processing of metal parts. It provides a high-performance solution for the most demanding metals and alloys in the industry.

Awards

GPAINNOVA is a technological platform based on the design and implementation of multidisciplinary innovative projects. Multiple brands within the group have received prestigious national and international awards and recognitions within a short period of time since GPAINNOVA was founded.

Schedule a visit

Our technology knows no borders. Neither does our team! Our DLyte on Tour regularly visits companies across Europe for free, to showcase at home our most advanced solutions for surface finishing in metal parts. Are you interested in an in-house demo at no cost?

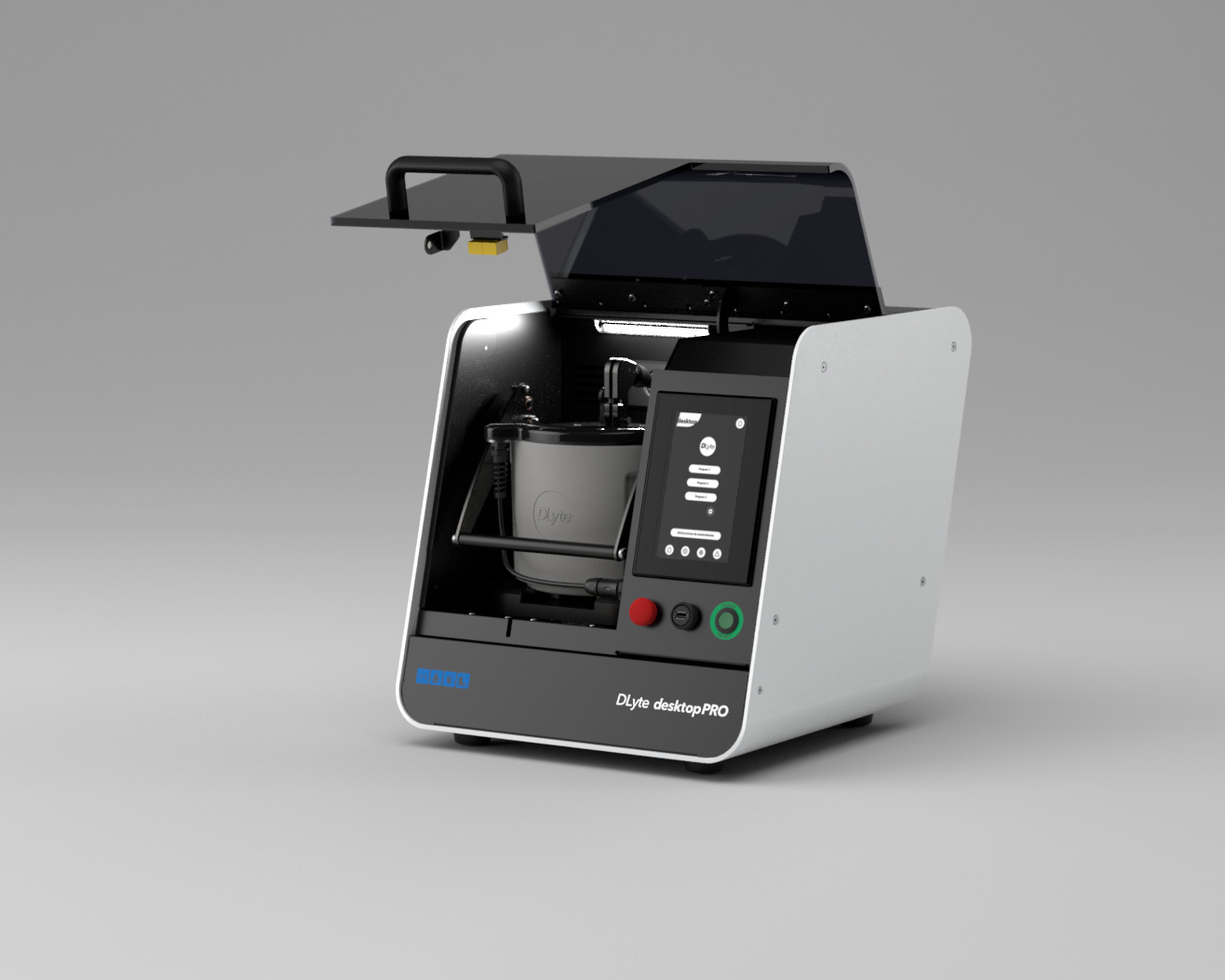

GPAINNOVA, the global leading company in dry electropolishing technology and specializing in marine robotics, medical devices and high performane power electronics, has just launched DLyte Desktop PRO, the very first ultra-compact dry electropolishing machine on the market.

It is a silent and compact machine designed to improve the work environment of thousands of small workshops and laboratories by replacing traditional hand polishing and hazardous materials with a safer option. This new equipment gathers all the advantages of any DLyte system currently available and allows any company, no matter the size, to access the disruptive dry electropolishing technology, including small labs, workshops, workrooms and SMEs needing a cost-effective solution for metal surface finishing processes. From grinding to mirror finishing, the new set-up offers an easy way to process any casting, sintering or milling metal parts.

The new DLyte Desktop PRO is affordable to any company because of its small dimensions (450 x 521 x 471 mm), its price and thefact of not requiring a special pre-existing electrical or compressed air installation. Thanks to its intuitive software, it is the perfect choice for any professional, because anyone without prior knowledge could learn how to use it easily.

Production has been underway since April 1 and orders are being accepted. The brand’s major distributors have already placed orders to deliver the first units in May 2021. Manufacturing of about 500 units is expected by March 2022.

There will be a worldwide livestream presentation on May 20.

The Way DLyte Desktop PRO Works

DLyte Desktop PRO combines the DryLyte technology performance with the ease of a plug-and-play system, offering a higher quality surface finishing than manual polishing processes. This technology guarantees minimal material removal, geometry preservation and a brilliant shine in every single metal piece. its automated surface finishing ensures uniformity between batches and parts so that every part meets the specifications required.

DLyte Desktop PRO works in a very similar way to the rest of DLyte equipment. Its metal surface finishing process stands out for its simplicity. First, a 3-liter container filled of solid electrolyte is placed in the machine in less than a minute. Then, the parts to be polished are clamped onto the holder finger, and placed into the equipment. Finally, the customer selects a program according to their needs. Once the fully automated cycle of 50-60 minutes is over, the metal piece is ready.

DLyte Desktop PRO is suitable for polishing cobalt-chrome (CoCr), titanium and stainless steel with the standard software, and additional metals with an optional software upgrade. This upgrade can treat several metals (for example, copper, brass, nickel alloys, aluminum and hard metals).

DLyte Desktop PRO’s Main Benefits

With the new DLyte Desktop PRO, metal frameworks are homogenously finished, up to 10 times faster than any other equipment. DLyte increases productivity and gives any technician the chance to focus on high-value activities while the equipment is treating the parts.

Its settings and opt-in advanced controls allow every professional to finish high-quality metal parts at the press of a button. This machine does not require special installation, since it operates with a standard household electrical plug.

DLyte Desktop PRO has been designed with high-quality components and outstanding design guaranteeing the lowest possible maintenance cost. This benefit, along with the process automation, reduces costs by up to 80%.

The new mechanical design ensures an exceptionally smooth and silent operation. The equipment is not dangerous for human health, since the automation of surface finishing with DLyte Desktop PRO protects technicians from exposure to the chemical agents at work. Additionally, the consumables used are safe and clean, without hazards of chemical liquid waste or dust during the process and handling.

In September 2018, DryLyte technologywas distinguished with the TCT Award for excellence in Additive Manufacturing Post-Processing. There are more than 400 satisfied customers who have taken the step towards polishing automation with DLyte.

DLyte Desktop PRO is already available for orders and it will be presented soon in a world premier live online event, on May 20. Anyone interested in learning more about the new machine can click on this link to join the event for free.

About GPAINNOVA

GPAINNOVA is a technology group born in 2013 in Barcelona, with subsidiaries in this city, Miami (Florida, USA), Hong Kong and Shenzhen (Mainland China) and specializing in surface metal finishing machinery, with DLyte and MURUA; medical devices with Respira Device.com Advanced, USV (Unmanned Surface Vehicles) with GPASEABOTS and high performance power electronics, with POWER INNOTECH. GPAINNOVA has a team of more than 150 professionals on staff and more than 35 engineers, and had a turnover of €15.8 million in 2020. The company has been selected by Financial Times among the 1,000 Europe’s Fastest Growing Companies in 2020 and 2021.

Find out more about DLyte Desktop PRO:

https://dlyte.com.cn/products/desktop-series/

DOWNLOAD THIS PRESS RELEASE IN:

English

French

German

Spanish

Catalan

For further information:

GPAINNOVA

C/ Maracaibo, 1, nau 2-6. 08030 Barcelona

Telephone: (+34) 931 256 536

www.gpainnova.com

粤ICP备2024252483号-1

Stay up-to-date with the latest innovations in the world of metal surface finishing by subscribing to our newsletter.